At Elite Recycling Solutions, our operations team is the backbone of our commitment to providing tailored, efficient, and sustainable waste management solutions across the UK. Their dedication ensures that every client receives personalised service, expert advice, and seamless communication, making waste management one less thing to worry about.

Led by the ever-capable Layla, our operations team is transforming how waste is managed across the UK. Combining strategy, passion, and precision to make a real difference. With Lucy-May providing close support and team members Chloe, Lucy, and Abbey showing unwavering commitment to client communication, this dedicated team keeps our day-to-day service running smoothly and ensures our Elite non-negotiables are upheld in every interaction.

A day in the life

From the moment the phone rings or an email pings, our operations team is ready. Whether it‘s a last-minute collection request, a query about recycling protocols, or assistance with compliance, they‘re always on hand to provide clear, actionable solutions. Their deep understanding of the waste hierarchy – Reduce, Reuse, Recycle, Recover – guides every decision, ensuring that clients not only meet but exceed their environmental targets.

Client-centric approach

What sets our team apart is their unwavering focus on client needs. They don‘t just manage waste; they build relationships. By understanding each client‘s unique challenges and goals, they craft bespoke strategies that optimise both environmental impact and financial efficiency. This personalised approach has earned us long-standing partnerships with businesses across various sectors, from fresh produce suppliers to large-scale manufacturers.

Seamless integration

Our operations team works in harmony with our nationwide network of partners, ensuring that every aspect of waste management, from collection to recycling, is handled with precision and care. Beyond day-to-day service delivery, the team collates and analyses waste data to produce bespoke client reports, empowering data-led decisions that optimise waste management practices. Their proactive communication and meticulous attention to detail mean clients receive timely updates, actionable insights, and the peace of mind that comes with knowing their waste is in capable hands.

Why it matters

In an industry where compliance and sustainability are paramount, our operations team stands as a testament to Elite Recycling Solutions‘ commitment to excellence. Their expertise not only helps businesses navigate complex waste regulations but also empowers them to achieve their environmental and financial objectives.

Want to learn more about how we can support your business?

Contact our team today hello@eliterecyclingsolutions.com – we’re here to help.

At Elite Recycling Solutions Ltd, our mission has always been clear: to deliver smarter, more sustainable waste solutions with unmatched flexibility and service. That mission has been shaped, from day one, by the passion and drive of our founders, and today, it continues to thrive through the dedication of our forward-thinking sales team.

Let’s take you behind the scenes to meet the team that’s expanding our reach, solving complex client needs, and driving Elite’s continued growth.

A legacy of growth, a team built for the future

Our sales success story began 18 years ago with Chris, whose tenacity and vision laid the foundation for the company. Alongside Fiona, whose resourcefulness and resilience helped build the Elite way of doing business, they turned a bold idea into a trusted name in waste and recycling services.

Now, under the dynamic leadership of David, our sales director, the sales team is growing from strength to strength. David brings energy, clarity, and a client-first mindset that continues to set us apart in a competitive industry.

“It’s not about making a sale, it’s about delivering value and building relationships that last,” says David.

Account management excellence: Alex and Enda

Alex and Enda are at the heart of our account management success. They work closely with existing clients to ensure their waste and recycling strategies continue to evolve with their business needs.

From optimising service schedules to offering proactive advice on waste reduction and cost efficiencies, Alex and Enda maintain strong, trusted relationships that help our clients succeed and stay one step ahead of environmental demands.

“We’re not just maintaining accounts, we’re helping our clients progress their environmental and sustainability credentials” says Enda. “That’s what makes it rewarding.”

New business, new solutions: Nick, Dale and Nathan

Driving forward our future growth are our new business developers, Nick, Dale and Nathan. Their focus is on listening to potential clients, understanding their unique waste challenges, and introducing solutions that align with both financial goals and sustainability targets.

Armed with Elite’s flexible, client-focused approach, Nick, Dale and Nathan don’t just sell – they solve. Their ability to identify the right solution, quickly and effectively, is helping businesses across the UK discover why Elite is different.

“We’re here to change the conversation around waste,” says Nick. “Elite doesn’t offer one-size-fits-all, we build bespoke solutions to drive operational efficiencies.”

The Elite advantage

What sets the sales team at Elite apart is simple: they’re not just delivering services, they’re delivering a promise. A promise of responsiveness, environmental leadership, and a personal approach that values every client relationship.

As we continue to grow, our sales team plays a central role in expanding our impact, ensuring that more businesses can benefit from a smarter, more sustainable way to manage waste.

Want to learn more about how we can support your business?

Contact our team today hello@eliterecyclingsolutions.com – we’re here to help.

At Elite Recycling Solutions Ltd, we know that delivering exceptional waste management solutions takes more than just efficient logistics; it takes a committed, knowledgeable team working together behind the scenes. Every call answered, every report sent, and every client relationship nurtured comes down to the people who make Elite what it is.

In this blog post, we’re proud to introduce you to the teams and leaders whose combined efforts ensure Elite continues to deliver industry-leading service with energy, flexibility, and care.

Operations: Where service meets consistency

Led by the ever-capable Layla, our operations team is the engine that keeps our day-to-day service running smoothly. With Lucy-May providing close support, and team members Chloe, Lucy and Abbey showing unwavering commitment to client communication, this team ensures our ‘Elite non-negotiables’ are upheld in every interaction.

From managing incoming job requests to supporting long-term recycling strategies, they’re always focused on delivering a consistent, friendly, and reliable experience for our clients.

“We set high standards for how we treat our clients, and our operations team meets those every single day,” says Layla. “It’s about being available, adaptable, and accountable.”

Finance and accounts: Accuracy with integrity

Behind every seamless client experience is a finance team you can trust. Guy , our longest-standing team member, leads with integrity and a deep understanding of Elite’s values. His dedication to continually improving our processes makes him a cornerstone of our internal standards.

Working alongside Guy is Suzi, who coordinates with multiple departments to ensure workflows run on time and invoices reflect the outstanding service we deliver. Her dedication to clarity and efficiency means clients always have the financial information they need, when they need it.

Sales and new business: Building relationships the Elite way

At the forefront of Elite’s growth is our dynamic sales and new business team, led by charismatic sales director David. Known for his energy and passion, David drives the team with purpose and vision.

Client relationships are nurtured with care by Enda and Alex, who provide excellent account management and ensure existing clients feel supported and valued. On the front lines of growth, Nick and Dale are making a powerful impact, bringing in new business with a clear point of difference: Elite’s innovative, flexible, client-focused approach.

“We don’t sell services, we solve problems,” says David. “And that’s why clients stay with us.”

Leadership: Driven by innovation and purpose

Elite benefits from the strong business ownership with Chris and Fiona , whose vision and direction continue to shape the company’s success. Their passion for sustainability, innovation, and team development sets the tone across every department.

With a focus on flexibility, responsiveness, and a truly client-centric approach, Chris and Fiona ensure Elite is not only competitive, but a leader in the recycling and waste management space.

“We’re proud of what we’ve built, but even more excited about where we’re going,” says Fiona. “Elite is about people, our clients and our team.”

The Elite difference

At Elite Recycling Solutions, we pride ourselves on being more than a service provider; we’re a trusted partner. What makes the difference? Our people. Across operations, finance, and sales, our team works in sync to deliver consistent service, expert advice, and an unmatched commitment to client success.

We’re not just reactive, we’re proactive. Not just efficient, but flexible. And not just another waste company - we’re Elite.

Want to see the Elite difference in action?

Get in touch with our team today, we’d love to show you what we can do.

Elite Recycling Solutions Ltd are proud to announce an exciting supply agreement with Mura Technology to be able to offer our clients exclusive access to their new and highly innovative Hyrdro-PRT advanced plastics recycling process.

As an approved UK-based commercial recycling business partner, we’re in a unique position to help our clients overcome the problem of plastics that have proven very difficult to recycle to date via traditional mechanical recycling processes, and otherwise are destined for landfill or incineration. These include mixed, post-use and previously unrecyclable plastics – particularly for those clients we serve in the food and manufacturing industries generating waste plastics with food residue.

Not only will this new technology provide our clients with cost savings, it also reduces their general waste and increases their recycling rates, contributing to a sustainable circular economy for plastics.

In the Government’s latest 6th March 2024 Spring budget, it was announced that there will be a 21% increase on landfill tax from April 2025, taking the tax up to £126.15. Whilst it is too soon to understand fully what impact this will have on the cost of incineration, with the Government confirming last year that energy from waste and incineration plants will be included in the UK Emissions Trading Scheme (ETS) from 2028, clearly the cost for general waste disposal will be increasing. Mura Technology’s process allows us to deliver increased recycling whilst reducing costs to our clients.

Another UK first means we’re ready to go for our clients

In fact, the first advanced plastic recycling plant using this unique and innovative recycling process in the world will soon open at the Wilton International science park in Teesside, right here in the UK and Elite can provide our clients access to it.

The purpose-built facility is ready to process Elite Recycling’s clients’ flexible and rigid mixed plastics. This means all materials currently considered ‘unrecyclable’, such as post-use, polypropylene (PP) and polyethylene (PE) plastics. This is waste that would have typically gone to landfill or incineration.

How does this unique plastics’ recycling process work?

Mura Technology’s advanced plastics recycling solution – known as Hydrothermal Plastic Recycling Technology, or Hydro-PRT – uses supercritical steam (water under high pressure and high temperature), to convert plastics into stable, premium hydrocarbon products, that can be used to manufacture new plastics.

Essentially, it converts plastics back into the chemical and oil products from which they originated.

Is a sustainable plastics economy even possible?

In short, yes. Mura Technology’s unique process and Elite Recycling’s partnership with them is just the first (but crucial) step in helping our UK-based clients recycle those previously difficult to recycle plastics; helping them to minimise costs and waste, while maximising their recycling rates.

The team here at Elite Recycling can offer organisations access to the new plastics recycling facility on Teesside, which has the capacity to produce 20 kilo-tonnes per annum (ktpa) of liquid hydrocarbon products.

What’s more, the plant has the scope to expand production capacity to over three times this initial size. So whatever the plastic recycling needs of our clients, we’re confident we can meet them.

How our clients and the environment will benefit from our partnership with Mura Technology:

- reducing costs

- reducing waste and carbon emissions – by diverting ‘unrecyclable’ plastic away from incineration and landfill

- enabling business compliance – through achieving their own Environmental, Social and Governance (ESG) and government-mandated waste recycling targets

- helping to create a circular economy for plastics.

A partnership that puts our clients and the environment first

Elite Recycling Solutions’ Managing Director, Chris Smits, said, ‘We’re really proud, and excited to be an approved UK-based commercial recycling business partner to Mura Technology. The relationship enables us to access this pioneering solution for our clients mixed, post-use and currently difficult to recycle plastics – particularly for those clients we serve in the food and manufacturing industries.’

He continued, ‘Mura Technology’s unique Hydro-PRT process will enable us to work closely with our clients to recycle those unrecyclable plastics, to deliver cost savings, reduce general waste to landfill or incineration and increase recycling rates, whilst playing a key part in driving our clients environmental and sustainability credentials.’

Chris concluded, ‘Mura Technology’s process fits perfectly into our leading-edge approach, where we deliver a complete range of innovative waste services and recycling solutions, all tailored to our clients’ specific needs.’

If you’d like to know more about our new UK-first partnership with Mura Technology and how it might benefit your business, simply call us 01920 872 221 or send a message to hello@eliterecyclingsolutions.com

At Elite Recycling Solutions we’ve talked long and often about the benefits of segregating waste.

We’ve worked equally hard to optimise the amount of waste our clients segregate so less of it ends up being incinerated or sent to landfill and more of it can be recycled or re-used to support the circular economy. But things are about to get more serious when it comes to segregating waste with the new Simpler Recycling regulations coming into force in March 2025. See gov.uk website.

Get it sorted – your waste, that is

The Simpler Recycling Regulations were introduced in 2023 by the Department for Environment, Food & Rural Affairs (Defra)

The aim was to reform household and business bin collections and crackdown on unscrupulous waste carriers while, delivering a boost to recycling rates and our protection of the environment.

For businesses, of course, simpler recycling is a little more complex. So in this article we’ll take a closer look at how the new regulations will impact your operation and what you can do about it.

So, what’s Simpler Recycling?

There’s no doubt that the recycling regulations – whether you’re at home or at work – can seem complex and confusing. Essentially then, Simpler Recycling is being introduced to make waste collections more straightforward.

The new regulations mean that by 31st March 2025, all businesses and other non-household premises in England with 10 or more full-time employees must separate plastic, paper and card, glass, metals (cans, tins and foil) and food waste from general waste. The goal is to save valuable resources from being discarded and provide fresh impetus to the circular economy here in the UK.

Note that organisations such as schools, hospitals and charities, for example, with 10 or more employees, are included. And that’s regardless of how many employees you might have on a site. Say you operate out of 10 locations but only have one employee in each, then these regulations do apply to your business.

Simpler Recycling will have comprehensive coverage

It’s no exaggeration to say that everyone in England will be affected by the new Simpler Recycling regulations. Here’s the all-inclusive shortlist:

- Businesses: both small and medium-sized enterprises (SMEs) (businesses with 10 or more full-time equivalent employees) and micro-firms (businesses with under 10 full-time equivalent employees).

- Non-household premises: hospitals, schools, colleges and universities, including what are known as Schedule 2 sites such as places of worship, penal institutes, charity shops, hostels and public meeting places.

- Households: all properties (from houses to flats including those above shops).

However, it’s important to note that the timeline for businesses and households are different, so please keep reading to discover the dates your enterprise will need to plan for.

What ‘required materials’ are included in Simpler Recycling?

Under this new legislation, by the 31st March 2025 your business must segregate the following materials into appropriate containers to enable their recycling and the saving of valuable resources. These are:

- Plastic (excluding plastic film)

- Glass

- Metal (cans, tins and foil)

- Paper and cardboard

- Food waste

What we don’t yet know

There is still some uncertainty about how these materials can be collected and Defra is currently reviewing this. Dry materials such as plastics, glass and metals, can all be co-mingled in one suitable container, which is generally currently referred to as dry mixed recycling (DMR). However paper and cardboard – as ‘fibres’ – must be collected separately so that their potential to be recycled is not reduced by contamination, although there may be some local flexibility to co-collect paper and card with other dry materials where separate collection is technically or economically impracticable.

In any event, food waste will have to be separated and collected from any other waste stream. And by the 31st March 2027, recyclable plastic film must be separated also.

The Simpler Recycling timeline

- By 31st March 2025

All businesses and non-household premises (with 10 or more full-time equivalent employees) must implement recycling practices for all recyclable waste streams. - By 31st March 2026

Local Authorities will be required to collect all six recyclable waste streams (excluding plastic film), from all households. They must collect food waste weekly. - By 31st March 2027

Micro-firms (with under 10 full-time equivalent employees) must comply with the new recycling requirements. Note this is subject to final confirmation from Defra.

Also by this date, all businesses and non-household premises must separate recyclable plastic films.

Start planning and preparing for Simpler Recycling now

Defra announced on the 29th Nov 2024 that they will continue to work with the sector and provide further guidance and tools to support preparation for Simpler Recycling implementation dates, with a particular focus on the 31st March 2025 deadline for businesses and relevant non-domestic premises.

Along with the increase in landfill tax rates in England coming into force in April 2025, there’s never been a better reason for your business to have more waste recycled and less sent as general waste.

And the team here at Elite Recycling can help you at every step toward the successful implementation of Simpler Recycling. Since 2007, we’ve been designing and delivering innovative, bespoke, cost-effective and end-to-end waste management solutions for businesses like yours – with the focus firmly on improving your operational and budgetary efficiencies by minimising waste and maximising revenue streams.

So if you’d like to discuss how your business might prepare and plan for the introduction of Simpler Recycling in March 2025, please feel free to call us on 01920 872 221 or email hello@eliterecyclingsolutions.com to discuss your requirements or book a free waste review.

In April 2025 Landfill Tax will rise to £126.15, while the lower rate will increase to £4.05 per tonne. Currently, the rates stand at £103.70 and £3.30, respectively.

This significant increase will impact all sections of the waste management industry, from local authorities to sectors such as food and construction.

Is there a solution to the problem of this new cost increase?

In short, yes. There is a new and innovative way businesses can protect their waste management budgets, ensure compliance, uphold environmental and sustainability credentials, and safeguard the countryside.

In this blog post, we’ll tell you how. Read on.

Elite Recycling – highly experienced and expert waste management

Since 2007, Elite Recycling has been designing and delivering innovative, bespoke, cost-effective, and end-to-end waste management solutions. Our focus is on improving our clients’ operational efficiency.

Over the years, we've helped clients remove and recycle a wide range of waste materials in ways that minimise costs and maximise revenue streams. Our strategic and planning capabilities position us ideally to help our clients prepare for the new increase in Landfill Tax, effective from spring next year.

Back to the future

The Landfill Tax, introduced in October 1996, encourages waste producers and the waste management industry to adopt more sustainable disposal alternatives. Since 2014, the tax has risen in line with the retail prices index (RPI).

In 2015 and 2018, collection of the tax was devolved to Scotland and Wales, respectively. Although technically three Landfill Tax regimes operate across the UK, all three governments keep their rates similar to deter ‘waste tourism’.

Will increasing Landfill Tax improve waste reduction behaviour?

To deter organisations from sending waste to landfill, there must be an effective circular economy alternative available – one that enables businesses to recycle waste, particularly plastic, in a simple, sustainable, and cost-effective way.

Thanks to Elite Recycling's partnership with Mura Technology, we have exclusive access to their unique and innovative Hydro-PRT recycling process, providing a solution to this challenge.

Introducing tomorrow’s plastic recycling solution today

Mura Technology’s pioneering Hydro-PRT recycling process allows us to recycle plastics that were previously difficult or impossible to recycle. This includes dirty, mixed post-use polypropylene (PP) and polyethylene (PE), including film, saving them from landfill and reducing disposal costs for our clients.

The first advanced plastic recycling plant using this process recently opened in Teesside. The Elite team is ready NOW to start recycling our clients’ plastic waste using this innovative method.

The benefits of advanced Hydro-PRT plastic recycling

Our partnership with Mura Technology means our clients can:

- Reduce the amount of plastics sent to landfill and the associated landfill tax

- Cut carbon emissions by up to 80% compared to incinerating plastic waste

- Increase recycling rates and achieve regulatory compliance, as well as enhance environmental and sustainability credentials

- Convert mixed, post-use, and hard-to-recycle plastics into high-value resources, creating value from otherwise wasted products

- Help protect the countryside and the planet

Time to reduce the plastics you send to landfill and the tax you pay on them

Our sustainable business practices are guided by the waste hierarchy: Reduce, Reuse, Recycle, Recover. Our partnership with Mura Technology and access to their Hydro-PRT technology exemplify these principles in action.

Act now to reduce the amount of plastic you send to landfill and avoid the higher rate of landfill tax starting April next year.

To find out more about how we can help solve your organisation’s recycling challenges with tailored, cost-effective, and sustainable waste management and disposal solutions, call 01920 872 221 or email hello@eliterecyclingsolutions.com

Change is a constant in business, and nowhere is this more evident than in the environmental sector. With complex and ever-evolving recycling and waste management regulations, staying compliant can feel like a challenge.

Since 2007 the team here at Elite Recycling has worked tirelessly with our clients to help them manage their waste with bespoke, end-to-end solutions that use recycling to minimise their environmental impact, costs and hassles and maximise their revenue streams.

Our unique, competitively priced waste management strategies support our clients throughout their entire waste removal and treatment process. As a result, we ensure they meet their legislative obligations while optimising the amount of waste they recycle.

With 2025 set to bring significant new environmental regulations, this article highlights our top five topics for the months ahead.

1. Simpler recycling

Simpler recycling is being introduced this year with the aim of making waste collections more straightforward.

The new regulations mean that by 31st March 2025, all businesses and other non-household premises in England with 10 or more full-time employees must separate plastic, paper and card, glass, metals (cans, tins and foil) and food waste from general waste. The goal is to save valuable resources from being discarded and provide fresh impetus to the circular economy here in the UK.

2. Food waste separation

As part of the Simpler recycling legislation, all businesses and non-household premises (again, with 10 or more full-time equivalent employees) must implement recycling practices for all recyclable waste streams, this includes food waste – no matter how much or little of it your business produces.

Food waste separation means that everything food-related – from plate scrapings, coffee grinds and tea bags to your employees’ uneaten lunch – must be separated out from your other waste, placed in a suitable container and collected for appropriate disposal.

3. Landfill tax increase

Get ready for a 21% increase in landfill. In April 2025 landfill tax will rise to £126.15, while the lower rate will increase to £4.05 per tonne. Currently, the rates stand at £103.70 and £3.30, respectively.

This significant increase will impact all sections of the waste management industry, from local authorities to sectors such as food and construction.

Careful planning and action now can help your business prepare for these increases in the Landfill Tax in the spring.

4. Extended Producer Responsibility (EPR) regulation

All UK-based organisations that handle and supply packaging to consumers and businesses are now subject to a regulation that impacts the way they manage their packaging.

The EPR regulation – which enhances the current producer responsibility regulation – changes the way you account for the type and volume of packaging you use and the way you recycle it.

Crucially, under the regulation, you should have been collecting the required packaging data from 1 January 2023. And while EPR fees have been deferred for a year (so no payments were required in 2024), you must still report your 2023 packaging data.

What’s more, in 2025 you will need to pay fees based on the data collected in 2024. And don’t forget that any fees due under previous regulations must continue to be paid.

So, if you’re an individual business, subsidiary or group; have an annual turnover of £1 million or more; are responsible for over 25 tonnes of packaging in a calendar year and carry out any of the ‘packaging activities’ mentioned in the EPR regulation, you must comply with that regulation.

5. Renew Hydro-PRT

Hydro-PRT is an exciting new technology that’s going to have a real impact in 2025. And here at Elite Recycling we can offer our clients exclusive access to it.

Mura Technology’s new and highly innovative Hydro-PRT advanced plastics recycling process is a pioneering way to recycle plastics that were previously difficult or impossible to recycle. This includes mixed, post-use and previously unrecyclable plastics – particularly for those clients we serve in the food and manufacturing industries generating waste plastics with food residue.

This isn’t science fiction. In fact, the first advanced plastic recycling plant using this process recently opened in Teesside and is already recycling our clients’ plastic waste using this innovative method.

As an approved UK-based commercial recycling business partner, we’re in a unique position to help you overcome the problem of disposing of plastics. Your business and the environment can benefit by:

- reducing costs

- reducing waste and carbon emissions – by diverting ‘unrecyclable’ plastic away from incineration and landfill

- enabling business compliance – through achieving both their own Environmental, Social and Governance (ESG) and government-mandated waste recycling targets

- helping to create a circular economy for plastics.

Not only will this new technology provide your organisation with cost savings, it also reduces your general waste while increasing your recycling rates, contributing to a sustainable circular economy for plastics.

Cut through the confusion to confidence and clarity

When it comes to planning and preparing for these new regulations it’s all about being aware and then being ready – and that’s where the team at Elite Recycling can really help.

As with most regulations, there are a number of variables at play. These range from the size of your organisation and the type of materials you use to the kind and quantity of waste you create. We provide detailed reporting on volume and value as well as green house gas emission savings to support your sustainability and environmental credentials.

Why not talk to us about your waste and recycling needs, its disposal and the impact of these new regulations on your operations? Then we can help you get your plan and strategy in place with confidence, freeing you up to focus on more important aspects of your business.

As Elite’s managing director, Chris Smits, comments, ‘We work in partnership with a wide range of clients to successfully create and deliver customised, cost-efficient and sustainable waste collection, disposal and recycling services. We’re ideally positioned to help you with effective reporting on all your waste streams to help you stay compliant, reduce costs and increase recycling rates and revenue streams.’

If you’d like to discuss how your business might plan and prepare for the impact of these new regulations in 2025, please don’t hesitate to call us on 01920 872 221 or email hello@eliterecyclingsolutions.com to discuss your requirements or book a free waste review.

UK-based organisations are subject to a regulation that impacts the way they manage their packaging.

The Extended Producer Responsibility (EPR) regulation – which enhances the current producer responsibility regulation – changes the way you account for the type and volume of packaging you use and the way you recycle it.

Crucially, under the regulation, you must collect the required packaging data from 1 January 2023. While EPR fees have been deferred for a year, meaning no payments are required in 2024, you must still report your 2023 packaging data. In 2025, you will need to pay fees based on the data collected in 2024. Additionally, any fees due under previous regulations must continue to be paid.

A wide-ranging regulation

The regulation applies to all UK organisations that handle and supply packaging to consumers and businesses.

Essentially, if you’re an individual business, subsidiary or group; have an annual turnover of £1 million or more; are responsible for over 25 tonnes of packaging in a calendar year and carry out any of the ‘packaging activities’ mentioned below, you must take action to comply with this regulation.

Those ‘packaging activities’ include:

- supplying packaging under your own brand or for another UK organisation,

- using ‘transit packaging’ to protect goods on the move,

- importing goods in packaging,

- selling, loaning or hiring out packaging, or

- owning an online marketplace.

Be aware, be ready – we can help

As with most regulations, there are a number of variables at play. These range from the size of your organisation, the type of materials you use and whether they go abroad, to buying packaging waste recovery notes (PRNs) or packaging waste export recovery notes (PERNs) to prove your packaging waste has been recycled correctly.

So you have to record and submit the right data about what’s happened to your packaging and pay the right fees to prove you’ve met the right recycling obligations. And as is often the case, non-compliance can lead to fines.

Make the process easier and more straightforward

Why not talk to the Elite Recycling team about accurate, timely reporting on your waste – including packaging – streams, so you can focus on more important aspects of your business.

As Elite’s managing director, Chris Smits, comments, ‘We’ve worked in partnership with a wide range of clients, to successfully create and deliver customised, cost-efficient, and sustainable waste collection, disposal and recycling services since 2007, so we’re ideally positioned to help you with effective reporting on all your waste streams. As a result, we can help you stay compliant with the EPR regulation.’

To find out more, please don’t hesitate to call us on 01920 872 221 or email hello@eliterecyclingsolutions.com

Recycle Now’s flagship annual celebration of recycling across the nation, Recycle Week 2024, is upon us.

This year’s nationwide event runs from the 14th to 20th October, with the theme of ‘Rescue Me’ and a focus on getting us all to rescue recyclable items from our rubbish.

Recycle Week really matters. It’s a time of the year where retailers, brands, waste management companies, trade associations, governments and the media come together to achieve one goal: to galvanise us all – whether that be business or individual – into recycling more of the right things, more often.

So what better time, then, to talk about re-use and you re-using more of your waste?

In this blog post, we’ll tell you more about the various ways you might be able to do just that to do your bit for our planet and your bottom line.

First, a word or two about waste

The definition of waste has been in use since 2008 and was based on the European Union’s (EU’s) Waste Framework Directive (WFD)1. Although it has recently been updated by UK regulation, the broad definition of waste remains the same: ‘Any substance or object…which the producer or the person in possession of it discards or intends or is required to discard'.

But here’s the (important) thing – if an item is capable of continued use (such as toner cartridges being returned for refill) or can be used as a by-product of another process as a raw material, there’s no need to class it as waste.

Which brings us nicely back around to re-use

Re-use commonly means the practice of using an item, whether for its original purpose – as in our toner cartridge example above (which is known as conventional re-use) – or to fulfil a different function (which is often called creative re-use or repurposing).

There are so many possibilities in re-using and repurposing waste

In June 2022, the World Economic Forum (WEF) published an article about the circular economy2. This included some truly innovative – as well as purely common sense – ideas. For example, various companies from as many countries around the world are:

- harvesting around 900 kilos of mushrooms a month from used coffee grounds

- using millions of ground down tennis balls to create a rubber crumb that’s then used in the construction of tennis courts

- collecting, shipping and tailoring bicycle inner tubes from cyclists in the UK to repurpose into products like belts, wallets, cases for tech items and soft furniture

- taking waste chewing gum, mixing it with a binder and natural dyes before turning it into skateboard wheels using injection moulding.

Another recent innovation includes re-manufacturing laptops to exacting technical standards using precision engineering and extensive checks to ensure consistent quality, with 99% of the original materials being re-used.

Here at Elite Recycling Solutions we’re doing our bit to help our clients do theirs

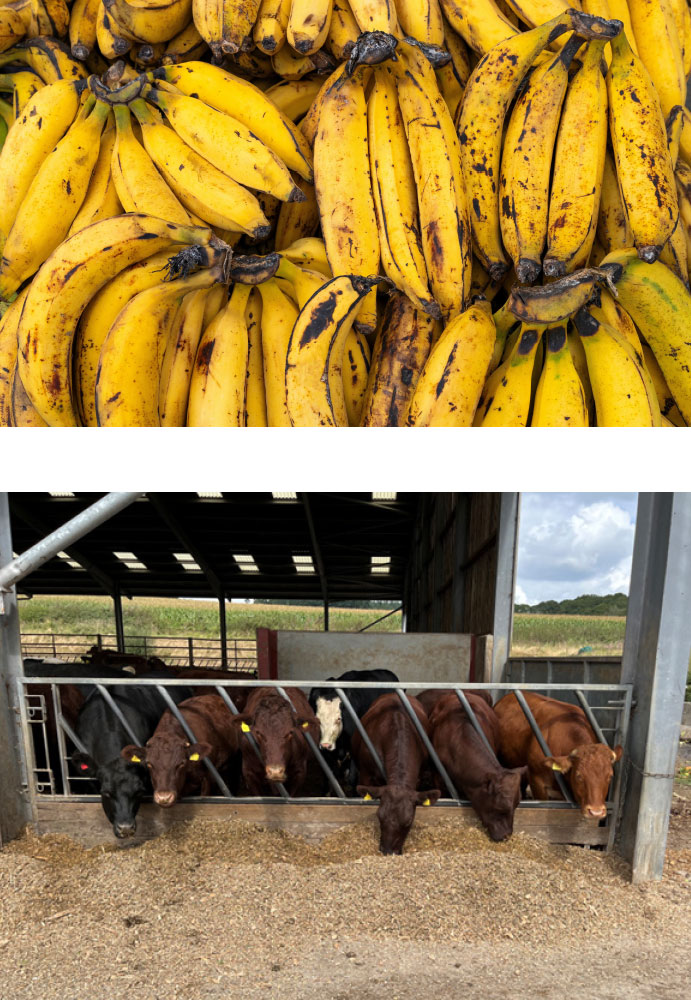

We’re constantly looking for ways to help our clients reduce waste through innovative or creative re-use. Some recent simple ideas have included:

- wooden pallets being given to a community garden project for re-use as furniture, fencing and planters

- fresh produce redistributed for use as cattle feed

- redundant chairs and tables going into local schools

- a particular over-ripe fruit being turned into one of the nation’s favourite tipples

- previously problematic and hard-to-recycle plastics being directed to an advanced recycling process – Hydro-PRT3 – which uses supercritical water to break the plastic back down into its constituent parts for re-use.

So what could your business do to re-use more?

We’ve already mentioned the humble toner cartridge, which can be refilled and re-used.

But what about donating used furniture, equipment or end of line products to other organisations (such as schools or charities) that can make good use of them.

Then there’s business-to-business online exchanges where you can offer used industrial materials and equipment for sale or swap.

More ambitiously, how about using grey water recycling systems to capture and redirect water to your toilets?

Think before you throw — how re-use benefits your bottom line

First and foremost, re-use reduces the amount of waste that needs to be transported to incineration or recycling outlets and thus reduces your costs and taxes accordingly.

There’s also the savings on the collection costs, as you’ll only be paying for the transport, not the disposal element.

Last but far from least, more re-use means consuming fewer natural resources and reducing your scope 3 emissions. Both of which minimise harm to our planet and maximise the reputation of your business and brand.

Put simply, re-use is a win-win. So if you’d like to discuss how your business might re-use more and waste less, please feel free to call us on 01920 872 221 or email hello@eliterecyclingsolutions.com for a confidential, no obligation chat.

1 EU Waste Framework Directive (WFD)

2 World Econimic Forum circular economy

3 Mixed Post-Use Plastics – Advanced recycling process Hydro-PRT

Elite are proud to announce that we have recently obtained ISO 14001 registration for our Environmental Management Systems (EMS). This remarkable achievement reflects our unwavering dedication to sustainable practices and responsible environmental stewardship. The ISO 14001 certification recognises our commitment to reducing our ecological footprint, improving operational efficiency, and delivering superior environmental performance.

Why ISO 14001 matters?

The ISO 14001 certification is an internationally recognised standard that sets the benchmark for effective environmental management systems. It ensures that organisations like Elite adhere to rigorous environmental standards and continuously strive for improvement. By obtaining this registration, we demonstrate our commitment to sustainability, regulatory compliance, and the preservation of natural resources.

Benefits to Elite

- Enhanced environmental performance: ISO 14001 certification empowers us to identify and address potential environmental risks, improving our overall performance. This includes the reduction of waste, energy consumption, and greenhouse gas emissions. As a result, we minimize our ecological impact and contribute to the global fight against climate change.

- Streamlined operations: The ISO 14001 standard encourages the adoption of efficient and sustainable processes throughout our organisation. By identifying opportunities for resource optimisation and waste reduction, we can enhance productivity, reduce costs, and strengthen our competitive advantage.

- Regulatory compliance: With ISO 14001 registration, we ensure strict compliance with environmental laws, regulations, and industry standards. This not only protects our business from legal liabilities but also fosters trust and credibility among our stakeholders.

Benefits to our clients

- Sustainable partner: Clients can be confident that by choosing Elite, they are partnering with an environmentally responsible organisation. We are committed to helping our clients achieve their sustainability goals and meet their own environmental targets.

- Enhanced reputation: By aligning with an ISO 14001-certified company, clients can enhance their own corporate image and reputation. It demonstrates their commitment to social responsibility and sustainability, which resonates positively with customers, investors, and the wider community.

- Supply chain advantages: Many organisations require their suppliers to have ISO 14001 certification as part of their procurement process. Our accreditation opens doors to new business opportunities, helping clients gain a competitive edge in the marketplace.

The importance of environmental benefits

The acquisition of ISO 14001 certification is not just about achieving regulatory compliance and reaping business benefits; it underscores the crucial role businesses play in protecting our planet. By adopting sustainable practices, we contribute to environmental conservation, mitigate climate change impacts, and foster a healthier and more sustainable future for generations to come.

Chris Smits, Elite Managing Director commented: ‘We are absolutely delighted to have gained another globally-recognised certification, ISO 14001. At Elite, we’re committed to continuously improving our standards and efficiency in delivering for our customers. This achievement reflects our dedication to improving efficiencies, minimising waste, and ensuring a sustainable future for ours and our clients’ operations as well as the environment.’

To sum it up

Obtaining ISO 14001 registration is a significant milestone for Elite. This achievement reinforces our teams commitment to environmental excellence, sustainable operations, and customer satisfaction. Through our dedication to responsible environmental management, we aim to inspire other businesses to follow suit and create a collective impact that will safeguard our planet's future. Together, let's embrace sustainability and forge a greener path forward.

To find out more, please don’t hesitate to call us on 01920 872 221 or email hello@eliterecyclingsolutions.com

From October 2023, people in England won’t be able to buy any single-use plastic cutlery products from any business – this includes retailers, takeaways, food vendors and the hospitality industry. Similar bans are already in place in Scotland and Wales.

Introducing the ban, the Department for the Environment, Food and Rural Affairs (Defra)1 said the ban will also cover single-use plastic bowls, trays and certain types of polystyrene cups and food containers.

Why plastic is off the menu

Recent estimates suggest that people in England use 2.7 billion items of single-use cutlery — most of which are plastic — and 721 million single-use plates per year. Sadly, only 10% of these items are recycled. If that many pieces of plastic cutlery were lined up they would go round the world over eight and a half times.

This kind of pollution takes hundreds of years to break down and inflicts serious damage on our seas, rivers and land. What’s more, it’s a major source of greenhouse gas emissions. That’s right from the production and manufacturing processes of the items themselves to the way they’re eventually disposed of.

According to research, plastic items relating to takeaway food and drink, including food containers and cutlery, make up the largest share of litter in the world’s oceans.

An international problem with local impact

But the devastation plastic pollution causes touches us much nearer home, too. Plastic was in the top 15 most littered items found on land in England by count in 2020.

Little wonder that around 95% of those that responded to a survey on the subject approved of a ban on single-use plastics.

Businesses will have to serve us without plastic

If consumers cannot buy these newly banned items anywhere in England it’s clearly going to impact those businesses that produce, supply and use them. The most visible of those businesses to most of us will be retailers, takeaways, food vendors and hospitality outlets.

Note that the ban will not apply to the plates, trays and bowls used as packaging in shelf-ready pre-packaged food items. These are to be included in the government’s plans for an Extended Producer Responsibility Scheme, which will incentivize producers to use packaging that can be recycled and meet higher recycling targets.

Do such bans work?

Bans in recent years have impacted the microbeads used in personal hygiene products as well as plastic straws, stirrers, cotton buds and carrier bags.

According to government figures, before plastic straws, stirrers and cotton buds were banned they collectively contributed to around 5.7% of marine litter. After the ban, the Great British Beach Clean 2021 reported cotton bud sticks had moved out of the UK’s top ten most common beach litter items.

Similarly, the charge for plastic carrier bags levied in supermarkets has successfully cut their sale by over 97%.

Plans being considered to further reduce the use of environmentally damaging products include a deposit-return scheme for drinks containers and a renewed focus on wet wipes, tobacco filters and sachets.

At Elite, we take both business and sustainability seriously

Chris Smits, Elite Recycling Solution’s Managing Director, commented, ‘The best way of protecting our planet and any business is to not use polluting plastics in the first place, so we welcome this new legislation. But we can help improve a business’s environmental footprint further still by converting their waste into reusable resources while helping them implement sustainable supply chains to improve productivity, efficiency, cost reduction and revenue growth through responsible recycling and waste removal.’

So is that a wrap for the use of plastics in business?

Richard Swannell, interim CEO of Waste & Resources Action Programme (WRAP), said, ‘We are in full support of this announcement by Defra, which marks important progress in the wholesale removal of problematic and unnecessary plastics that can end up as plastic pollution.’

Richard went on to comment on WRAP’s work with the nation’s businesses, ‘WRAP is working with UK businesses to meet ambitious targets in this important area, and our latest results show an 84% reduction in problematic and unnecessary single use plastics by our UK Plastics Pact members since 2018.’1

If you’d like to know more about this new single-use plastics regulation and how it might affect your business, simply call us on 01920 872 221, send a message through our contact form or email hello@eliterecyclingsolutions.com

After some time spent beavering away behind the scenes – well, we wanted it to be ‘just so’ – we’re proud and delighted to launch our new client portal.

From our website and with just a user name and password, our clients can get fast, simple, streamlined but, of course, secure access to a wide range of useful resources relating to their business. These include duty of care and financial documents, as well as new and improved bespoke reporting. These include duty of care and financial documents, as well as new and improved bespoke reporting.

A steer on your recycling from your dashboard

With user-friendly design, multiple logins able to be accessed simultaneously and easy navigation, clients can gain access to:

- landfill diversion statistics and CO2 highlights

- recycling performance

- information on service success rates and any collection, delivery, driver or wasted journey issues

- breakdowns of the different waste streams for which we provide services, and

- news updates, developments and announcements from us.

Reports, documents and useful historical detail

Isn’t it always the case that when you want a document, it proves elusive? So from the dashboard, clients can also view and download a variety of reports and useful documents. These include:

- reports on all volumes and values for completed services

- reports on financials for rebateable recyclables

- container and collection information, so clients can quickly see what containers they’re holding and where (such as skips, roros and bins) on site, and request services, and

- any uploaded documents, such as machinery agreements (for rentals, service and maintenance, for example) and duty of care documents, like the annual WTNS.

Doing a little bit more for our clients and the planet

By providing our clients with a fast and easy to use portal, we help them to keep track of, and improve, their environmental, waste disposal, recycling and sustainability commitments. This benefits their business and, of course, the planet.

If you’re a client of ours and would like any assistance in using the new portal, please do not hesitate to get in touch. Simply call us 01920 872 221 or send a message to hello@eliterecyclingsolutions.com

As we all know, cardboard is a popular packaging material. It’s highly versatile, light but strong, comes in a wide range of roll and box sizes, is way more durable than you’d think and is easy for a business to brand. Of course, the growth in online shopping has boosted cardboard packaging’s popularity further still in recent years.

Little wonder then that more than 15% of the money we spend on products pays for packaging, some of which can end up in the bin.

However, cardboard – particularly boxes – does have two key advantages over alternative packaging materials. Firstly, it’s reusable in its original form if handled correctly. Secondly, it’s simple to recycle as art of what’s known as the ‘circular economy’ or ‘paper loop'.

A virtuous circle

Figures vary but it’s reckoned that although we use more than 12.5 million tonnes of paper and cardboard here in the UK every year, over 70% of the fibre used to manufacture it is from recovered materials.

That virtuous circle is good but we could do better. Around five million tonnes of waste paper is still sent to landfill or incineration each year.

The benefits of recycling cardboard

The more we recycle cardboard:

- less goes to landfill,

- fewer trees are cut down (17 trees are saved per tonne of recycled cardboard),

- less energy gets used (as much as 4000kW of electricity is saved per tonne of cardboard recycled)

- less greenhouse gas emissions are created, and

- less water is wasted (about 7000 tonnes of water is saved per tonne of cardboard recycled).

A Fully Automatic Channel baling machine for one of Britain’s finest family-run food

service businesses

As part of our sustainable business and environmentally-friendly practices – and as defined by the

principles of the waste hierarchy: Reduce, Re-use, Recycle, Recover – we’re keen on utilising technology to

help our clients reduce the their impact and the amount that ends up as waste.

And as we already collect and supply a significant volume of all grades of paper and cardboard waste for recycling, we were well positioned to help a national food service client source the right fully automatic baling machine to meet their cardboard recycling needs, and then install their new resource.

Our client’s new fully automatic baling machine enables them to quickly, easily and cost effectively compact and bale loose cardboard boxes, reducing the amount of space their waste takes up while awaiting recycling. Baling also reduces their need for stand-alone recycling bins, which can also take up a lot of valuable space on site.

The many benefits of a baling machine

The fully automatic baler we specified for our client was sourced from Witham Mills Engineering, one of

the UK’s leading baler suppliers of waste management equipment and a company Elite have a close working

partnership with.

First and foremost, baling waste cardboard with a fully automatic machine actually enables our client to recycle even more cardboard. It gives them the opportunity to back haul cardboard from their other sites and customers for baling, as the process is now far faster and easier than they’d previously experienced. This helps generate increased revenue form cardboard waste.

What’s more, having chosen a fully automatic machine that can process four tonnes an hour, their baling machine is well suited to 24 hour operation, should demand require it.

Further labour savings are gained from the baling machine’s fully automated conveyor feed and self-tying, so reducing the need for hands-on effort. It also maximises bale volume and density and, therefore, revenue from their waste cardboard.

And with the specialist equipment from Witham Mills Engineering having a well-earned reputation for being robust, reliable and built to last with safety in mind: we were delighted to recommend their solution.

Last but far from least – and crucial to an environmentally conscious enterprise like Elite – the Witham Engineering automatic balers offer low power consumption.

The perfect partnership

Commenting on the installation of the new baling machine, Elite’s Managing Director, Chris Smits, said,

‘As our client has a number of depots around the UK, is highly innovative and is a fourth generation family

run business that puts a premium on personal customer service, the Elite and Witham Engineering teams were a

perfect fit partner for them in their search for a baling solution'.

If you’d like to know more about the various ways we can help you reduce your packaging waste and achieve your environmental objectives, please don’t hesitate to call us on 01920 872 221 or send a message hello@eliterecyclingsolutions.com

Back in 2018, the United Nations Food and Agriculture Organisation (UNFAO) reported that some 1.6 billion tonnes of food, worth approximately $1.2 trillion, went to waste every year around the world – about one third of all the food the planet produces.

If that figure was not staggering and shameful enough, the same report also stated that around 815 million of the 7.6 billion people in the world (or nearly 11% of the population) were suffering from chronic undernourishment.

However, the reality was actually worse. A more recent publication of major new studies on global food loss and waste – which included the United Nations Environment Programme (UNEP) Food Waste Index Report 20211, developed in collaboration with WRAP, and Driven to Waste: Global Food Loss on Farms, from the WWF and Tesco – suggests that over 40% of food produced globally may be going to waste, even higher than previously feared.

When thought for food is no longer enough

WRAP (Waste & Resources Action Programme) is a British registered charity launched in 2000. It works with local and national governments, businesses, communities and people to reduce waste, develop sustainable products and use resources more efficiently.

WRAP’s food waste reduction roadmap has grown in renown and stature across the world and now they work internationally, having recently partnered with UNEP and UNFAO to develop the ‘Think, Eat, Save’ global food waste guidance tool.

The organisation’s most recent report, published in September 2021, was able to report very positive progress in the war to reduce food waste.

The WRAP Food Waste Reduction Roadmap Progress Report1

With the aim of helping the UK to achieve Sustainable Development Goal (SDG) 12.3, as part of the nation’s strategy to reach net zero, an increasing number of businesses are committing to the Food Waste Reduction Roadmap and implementing a ‘Target, Measure, Act’ policy to improve their efficiency and resilience.

Just by achieving SDG 12.3 it’s reckoned that the UK would deliver an annual reduction in farm to fork food waste of 3.5 million tonnes by 2030, saving food worth £10 billion a year. That’s a halving of all UK food waste.

The good news is that in the past year (from September 2020 to September 2021) the number of businesses joining WRAP’s scheme has increased from 261 to 314.

It’s important to note that the roadmap includes all main food sectors from production and manufacture to retail and hospitality and service.

These numbers add up to major improvements in food waste

The roadmap report’s many positives include:

- 21% growth in the number of businesses implementing ‘Target, Measure, Act’ and providing data to support it,

- one-third of the UK’s large food businesses (with over 60% of sector turnover) now measuring performance,

- around 140 businesses providing year-on-year data have reported a 17% reduction in food waste, worth £365m or £1m per day,

- this equates to a 13 to 15% reduction in waste per tonne of food handled,

- an estimated 670,000 tonnes of green house gas emissions have been saved through 251,000 tonnes less food being wasted,

- some 60,000 tonnes of food was redistributed by businesses committed to the initiative, providing around 145 million meals.

Embedding ‘Target, Measure, Act’ into enterprise culture and operations is seen as an increasingly important way to help food businesses manage their resources as efficiently as possible – minimising waste and cost, maximising profitability and environmental benefit.

This not only helps businesses to increase their resilience and better meet their statutory obligations, but also ensures that any food surplus is put to good use rather than ending up as landfill.

We never let a recycling opportunity go to waste

Since our launch in 2007, the team here at Elite has developed proven expertise in creating and delivering innovative ways for some of the UK’s leading fresh produce suppliers and food processing businesses to reduce waste and recycle. We manage all types of organic waste streams and by segregating and reducing, helping our customers to meet their environmental targets and much more besides.

Our aim is to work in partnership with clients to determine the best way to segregate and reduce food waste in line with WRAP’s goals and the UK’s net zero ambitions, hence reducing the amount that ends up in landfill.

Where food waste is unavoidable we work to the principles of the waste hierarchy: Reduce, Re-use, Recycle, Recover. In addition, we’ll also work closely with our clients on recycling solutions for food contaminated packaging.

Commenting on the latest WRAP Food Waste Reduction Roadmap Progress Report, Elite’s Managing Director, Chris Smits, said, ‘My own background was originally in supplying fresh produce to some of the UK’s leading retailers. In fact, other members of our senior team also have agri-food and horticultural backgrounds. So we’re passionate about leading our customers on a path to reduce food waste in line with WRAP’s goals.’

Chris continued, ‘This latest roadmap report from WRAP not only provides clear and actionable solutions to what is a complex problem but it also makes really encouraging reading. It’s fantastic to see the increasing number of organisations committing to the roadmap, with an impressive 30 to 40% of the UK’s food and drink businesses (representing over 60% of the sector’s turnover) now measuring performance and taking action.’

To find out more about the ways in which we could help you reduce your food waste and achieve your environmental objectives, please don’t hesitate to call us on 01920 872 221 or visit Contact Us on this site and send us a message.

See the full WRAP Food Waste Reduction Roadmap Progress Report for 2021

1 United Nations Environment Programme (UNEP) Food Waste Index Report 2021

Here at Elite we work closely with businesses across the UK to help them efficiently, safely and cost-effectively dispose of their waste, via the principles of the waste hierarchy: Reduce, Re-use, Recycle, Recover.

It’s how we enable organisations to meet their environmental targets today while guiding them to achieve the evolving obligations of tomorrow.

Because we offer innovative, tailored, uniquely designed and sustainable recycling solutions for our business partners – all delivered with unparalleled, highly personal customer service – we know how important it is to listen closely to every customer requirement.

And to give us additional ears and eyes out there in this vibrant industry, we’re proud and delighted to announce that Enda Browne has joined the Elite team as our newest Business Development Manager.

Introducing Enda Browne

Enda comes to us with over 20 years of experience in various customer service roles across a wide range of industry sectors; most recently in Anaerobic Digestion feedstock waste procurement and site management.

Enda also brings to the table FMCG packaging purchasing and contract negotiation experience, as well as the knowledge he gained in pub and restaurant management earlier in his career.

We’re all looking forward to Enda utilising his experience, expertise and capabilities to ensure all our clients receive the very best advice, service and economical solutions to their waste disposal requirements, while helping them to adhere to current Duty of Care obligations and apply UK waste hierarchy criteria to all their waste streams for optimal efficiency.

Enda’s knowledge and skills have been honed with professional qualifications in a range of subjects, from a Level 4 in Anaerobic Digestion from Wamitab and the Complete Skilled Negotiator via The GAP Partnership to a CIPS Certificate in Purchasing & Supply.

A key part of our growing team

Enda’s appointment is all part of our continued and planned growth and he will be working closely with our operations and account management teams to continue to put our customers’ evolving needs first.

To find out more about this new appointment or how our services might benefit your operations, please don’t hesitate to call us on 01920 872 221 or contact us on this site.

If you’d like to contact Enda directly, simply call him on either (mobile) 07942 959 697 or (office) 01920 872 221. Alternatively, please send an e-mail to enda@eliterecyclingsolutions.com